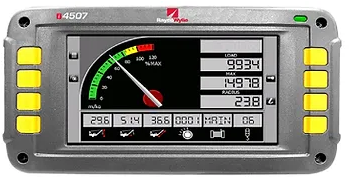

i4500 LMI-RCI

LOAD MOMENT Indicators & RATED CAPACITY Indicators

Load moment indicators (LMI) and rated capacity indicators (RCI) are the most essential operator aid for protecting your crane from an overload accident. Both systems monitor the essential information the crane operator needs to know. The crane LMI or crane RCI shows the operator the weight of the load being lifted, the capacity at that radius, the boom angle, length, radius, and anti-two block (ATB) warning.

There are several different sensors and designs used to monitor this information. LMI systems measure the force on the boom. Usually, this is on a telescopic boom crane and done with pressure sensors on the rod and bore side of the boom lift cylinder. RCI systems directly measure the tension of the hoist line. Typically, this is done with a load link, pin, or dynamometer.

Rayco/Wylie built the first crane overload indicator in 1934 and offers the latest technology and design for crane LMI & crane RCI systems today. We supply LMI and RCI systems for all types of cranes. The i4500 LMI / RCI is available for small carry deck cranes, large lattice cranes, tower cranes, offshore cranes, and everything in between. The i4500 comes in three screen sizes. (4.3”, 7” and 10”). It uses a CANbus network for easy troubleshooting and diagnostics. Calibration data can be uploaded or downloaded by USB. There is an optional data logger that can be used to record all the lifting activity.

i4500 LMI for

Telescopic Cranes

The i4500 LMI kit on telescopic boom cranes uses pressure transducers on the boom lift cylinder to measure the load on the boom along with a cable reel for measuring the boom angle and length. This is the most accurate way to measure the load and covers both hoists with one set of sensors. The pressure transducers are small and installed on the rod and bore side of the lift cylinder so there are no moving parts. Pressure transducer systems are the preferred LMI for crane OEM’s. Long term they are the most trouble-free, low-maintenance, and accurate crane LMI systems.

i4507 RCI for

Lattice Cranes

The i4507 (7” display) RCI on lattice cranes use a variety of sensors depending on what will work best on the specific model crane. Often the system will use two dynamometers or a dynamometer and dead-end load link along with the boom angle sensor and ATB switch assembly. Cranes with luffing jibs will add a 2nd angle sensor and some cranes will use a slew sensor to measure 360-degree rotation. Other optional sensors include list angle sensors for cranes on barges or windspeed sensors mounted at the boom tip. For large lattice cranes, the RCI system is the most important operator aid for safety and efficiency.

i4507 RCI for

Offshore Cranes

The i4507 (7” display) RCI on the lattice and fixed boom offshore cranes use a variety of sensors depending on what will work best on the specific model crane. The common sensors are dead-end load links, dynamometers, angles sensors, and ATB switch assemblies. All the sensors came in a marine duty version, usually stainless steel. I4507 systems are also available for cranes in hazardous gas areas or class 1 div 2 zones for the boom or cab. RCI systems on offshore platform cranes are critical to the safety and efficiency of the vessel and a required operator aid in most cases.

i4507 LMI for

Grove AT422T

The custom i4507 LMI is designed to replace the obsolete PAT Hirshmann OEM system that came on the Grove AT422T military crane. The new system includes the i4507 cab-mounted display along with several sensors that are mounted on the crane boom. It was specifically designed to replace the original PAT LMI system. The i4507 display will show the crane operator the capacity, load, angle, radius, and two-block warning for the crane. It monitors all the same information as the original system but in a new, updated, easier-to-use display.

i3500 to i4500

Upgrade Kit

The obsolete i3500 display found on the Grove and Shuttlelift carry deck cranes can be upgraded and replaced by the new i4500 display. This is an easy upgrade that only requires a minimal quick calibration. The new i4500 display will show the crane operator the capacity, load, angle, radius, and two-block. With warnings for overload and A2B. It monitors all the same information as the original system but in a modern, updated, easy to use display.

i4507 LMI for

Link-Belt HTC 8665

The i4507 LMI 8665 custom kit is designed to replace the obsolete Greer LMI that came on the Link-Belt HTC8665 cranes. We designed this kit with Link-Belts approval. This is a completely new LMI, including the i4507 7” full-color display, custom software, cable reel, pressure transducers, ATB switches, ETCS control box, foot pedal, telescope speed control dial, connecting cables, and hardware. This i4507 LMI kit will monitor all the same information as the original system, including load, capacity, % of capacity, boom length, angle, radius, and ATB. It has the same “A” and “B” boom capacities as the original system.